Client Information

Paradeep Phosphates Ltd (PPL) has their fertilizer production unit at Paradeep comprising Sulphuric Acid, Phosphoric Acid, Granulation Plants, off-sites & utilities. They import raw materials required for the manufacture of phosphatic fertilizers like ammonia, urea, rock phosphate, sulphur, potash. Paradeep Phosphates Ltd (“Owner”) has a manufacturing complex in Paradeep, Odisha. They have 3 sulphuric acid plants with design capacities of 2 X 1200 TPD (A&B Stream), Lurgi Technology and commissioned in 1991-92. Both plants have been retrofitted in 2017-18 with MECS HRS technology where IAT towers were replaced with HRS towers and common HRS boilers were installed. Third plant 2000 TPD (C- stream) of MECS design with HRS technology has been commissioned in 2016. Now it is being planned to add another Sulphuric Acid Plant of 1,500 TPD capacity. New plant will have HRS Technology for LP steam generation.

Project Information

PPL had increased their phosphoric acid production capacity, which required additional sulphuric acid. They planned to build a new 1,500 TPD Sulphuric Acid Plant at Paradeep to meet additional sulphuric acid requirement. There was a plant of 1500 TPD capacity which had not been installed and equipment were in port. It was decided to buy that unused 1500 TPD Sulphuric Acid Plant and install it at Paradeep site.

Work Done by Our Company

We are involved on this project from concept to commissioning. We started off with preparing a bankable project feasibility report including development of financial model. We were involved in visiting the physical storage location of the plant equipment in Dunkirk, France to assess it’s suitability for use at the Paradeep site. We prepared a report and based on the same it was decided by PPL management to proceed further. Thereafter we prepared enquiry/bid documents for selection of engineering company for doing Detail Engineering work. We were involved in preparing bid evaluation of offers submitted by various Indian engineering companies and finalization/selection of detail engineering company. We are playing roles as following during project execution & commissioning:

- Project Management Consultant (PMC) Services for new 1,550 TPD Sulphuric Acid Plant PMC Services, acting as Owner’s Engineer to advise Owner for basic & detail engineering, approval of all engineering documents/drawings and advising during project execution

- Tail Gas Scrubber Design for new 1,500 TPD Sulphuric Acid Plant We have provided complete basic & detail engineering package for Alkali Scrubber and are advising the client during project execution.

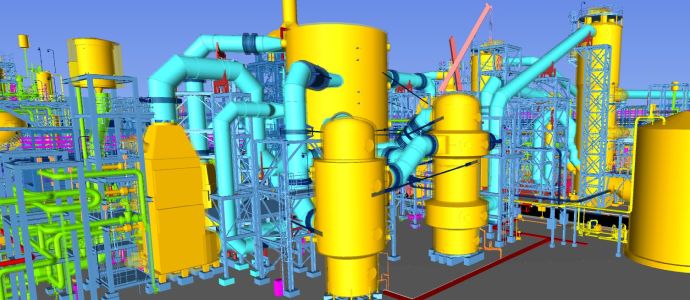

Project Gallery